JPE Industry Insights | From Structural Optimization to Sealing Performance: Highlights of the Trunnion Ball Valves Series

2025-07-17

Industry Knowledge Popularization

In high-pressure and high-risk fluid transmission environments, valves are not merely switching components—they serve as guardians of the entire system’s safety and efficiency. Drawing on its solid R&D capabilities in high-pressure technology, JPE has launched the TNBV series trunnion ball valves, aiming to provide stable and reliable fluid control solutions for demanding conditions such as high-pressure environments, frequent operations, and corrosive media. Featuring a trunnion-supported structure combined with a high-strength valve body and multi-sealing systems, the series integrates three key performance aspects: pressure resistance, durability, and ease of maintenance.

Compared to traditional floating ball valves, the trunnion design allows the internal ball to be secured between upper and lower bearings, which reduces operating torque, mitigates seat wear, and enhances overall sealing lifespan and operational stability. It is especially suitable for environments with high pressure differentials and frequent switching.

Materials and Structural Configuration Supporting Long-Term Reliability

The valve body of the TNBV trunnion ball valve is made of SS316L stainless steel, which offers excellent corrosion resistance and mechanical strength, making it suitable for most chemical fluids and industrial gases. The internal sealing components are equipped with three standard materials: FKM (fluoroelastomer), which offers good heat resistance and chemical compatibility, making it suitable for general industrial use; PTFE (polytetrafluoroethylene), which features low friction and high chemical inertness, enhancing smooth opening and closing; and PEEK (polyether ether ketone), which provides mechanical strength and dimensional stability under high-temperature and high-pressure conditions, and is often used in more demanding process systems.

This material configuration allows the TNBV trunnion ball valve to flexibly respond to wide temperature variations and complex media conditions, while maintaining structural integrity and reliable sealing during long-term use.

Every Unit Tested to Ensure Operational Safety and Consistency

Before leaving the factory, every TNBV valve undergoes functional and sealing testing using nitrogen at 500 psig to ensure responsive operation and zero leakage. This testing process not only ensures product consistency but also guarantees the valve’s immediate and stable functionality after installation. In addition, the TNBV features a blowout-proof stem design that prevents stem ejection caused by improper operation or sudden internal pressure surges, thereby enhancing overall operational safety. In terms of maintenance convenience, the TNBV adopts a modular assembly that allows for quick replacement of seals or localized repair, minimizing downtime and reducing maintenance workload.

Structural Flexibility and Versatile Options to Meet Varied Application Needs

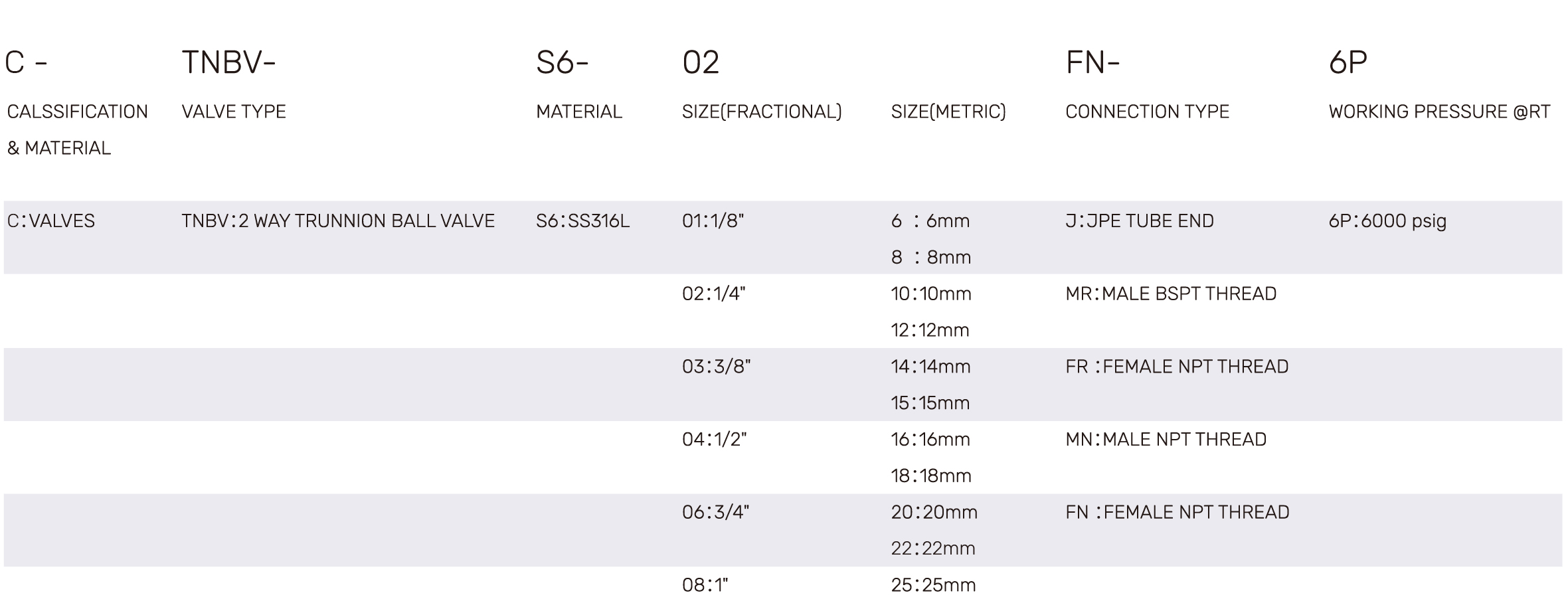

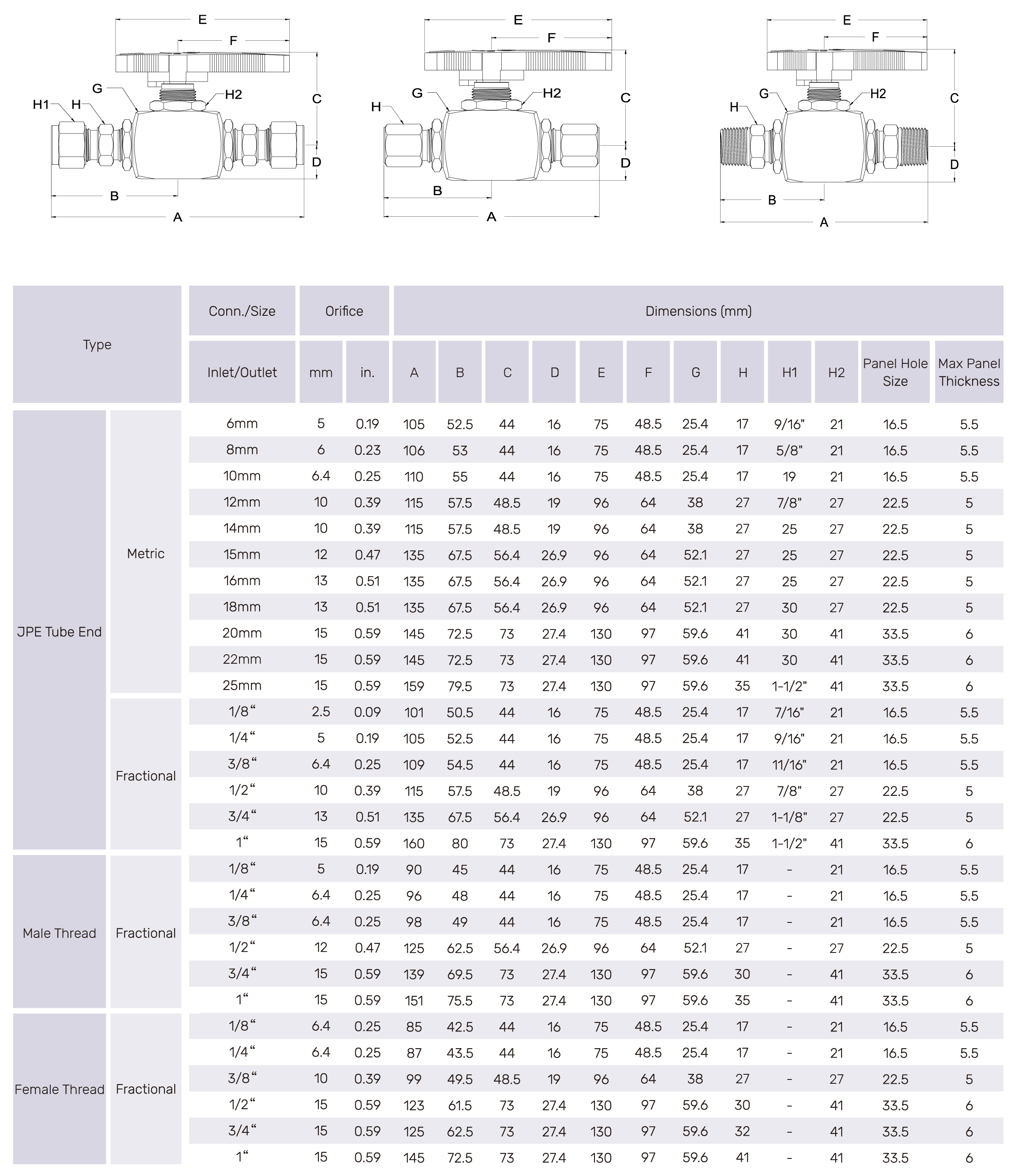

To accommodate different system structures and piping specifications, the TNBV series offers a variety of port configurations, including the commonly used JPE compression fittings and threaded connections. It supports a maximum working pressure of up to 6000 psig (approximately 414 bar), making it applicable to a wide range of media, including high-pressure gases, chemicals, industrial solvents, heat transfer fluids, and process liquids. Typical applications include petrochemical equipment, gas cylinder filling systems, precision instrumentation piping, automated process control, and high-pressure transport in the energy sector.

The TNBV can also be applied in High-pressure sampling systems, functioning as a key switching component that enhances the sealing integrity and operational stability of the sampling process. This structural flexibility and specification versatility make the TNBV a highly integrable industrial valve solution, easily adaptable to both new systems and existing system upgrades, ensuring simultaneous improvement in control efficiency and operational safety.

Combining trunnion-supported structure, corrosion-resistant materials, multi-sealing components, and modular design, the TNBV trunnion ball valve delivers reliable pressure control performance and maintenance convenience. It is suitable for various high-load working conditions and complex media systems. As part of JPE’s ball valve product line, the TNBV’s demonstrated stability and flexibility have been widely adopted in fluid control fields, making it one of the mature solutions for high-pressure and precision control demands.