JPE Technical Insights | Building Precise and Safe Sampling Systems to Support Modern Industry

2025-05-23

Featured Products

In modern industrial processes, a sampling system is a device designed to safely collect liquid or gas samples from pipelines. Its primary purpose is to deliver representative samples to laboratories for analysis. Whether in the chemical, petrochemical, energy, or high-tech sectors, the ability to collect samples accurately and safely has a direct impact on subsequent quality analysis, process control, and environmental compliance.

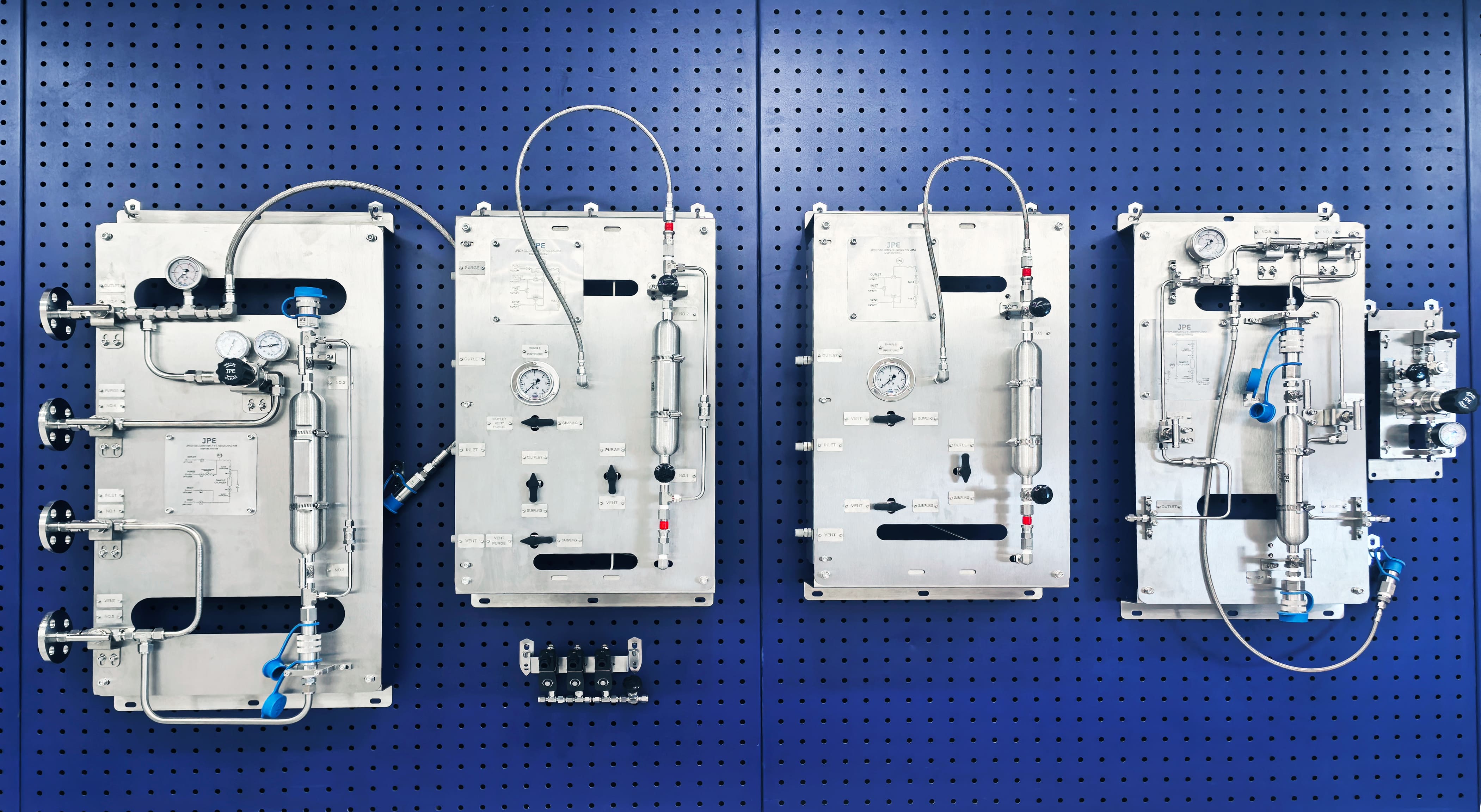

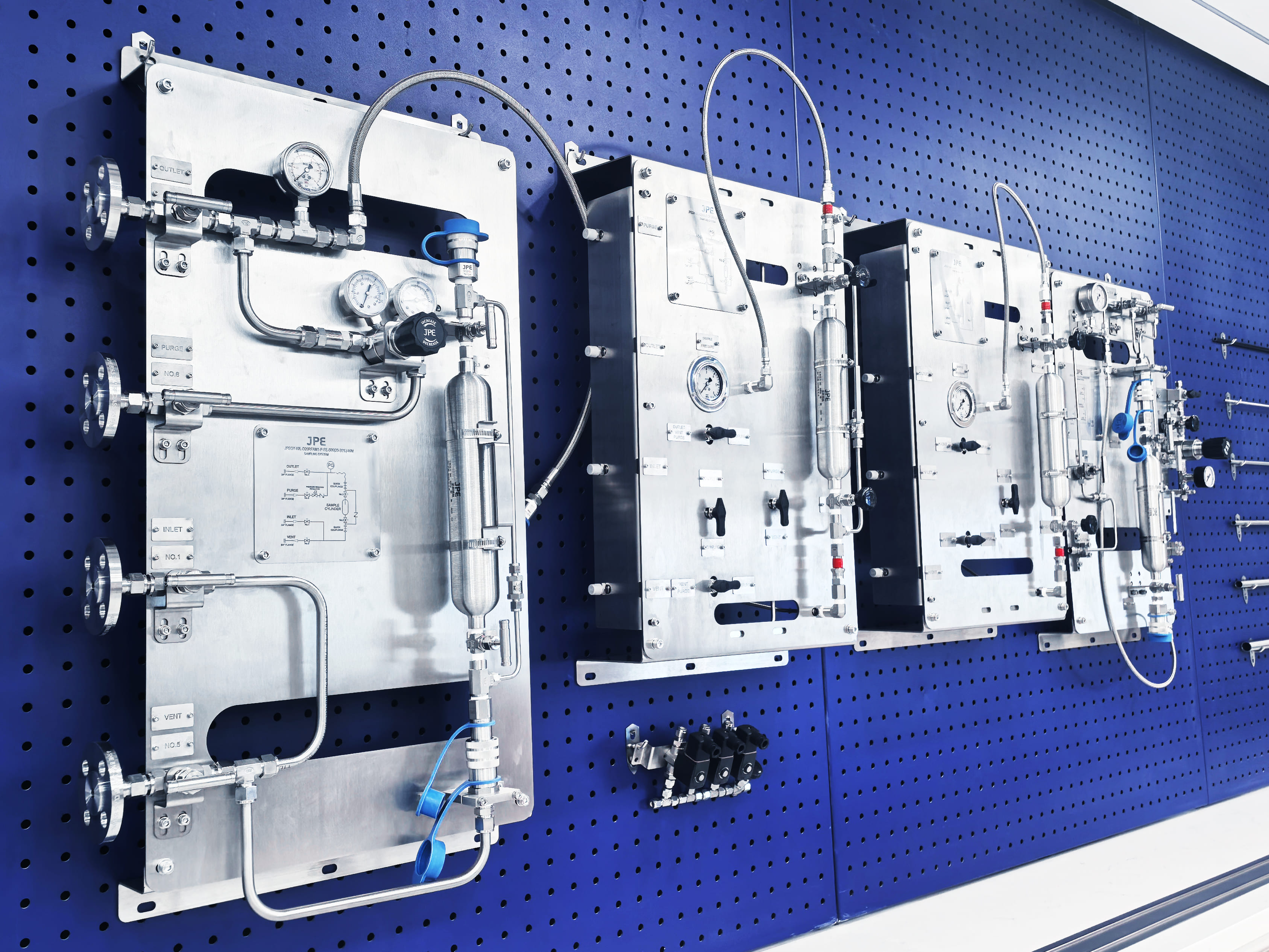

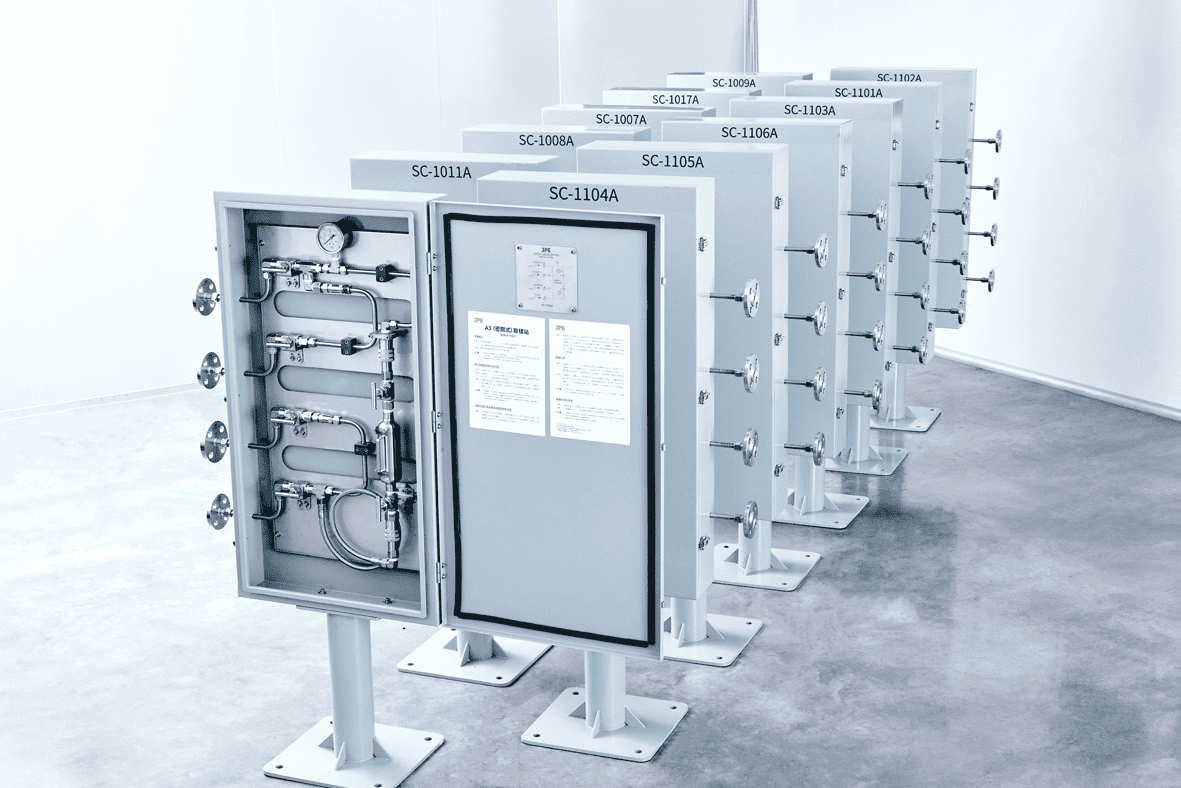

JPE’s sampling systems are engineered and manufactured using high-quality, reliable components. With custom-built designs to meet specific applications and needs, optional accessories include pressure gauges, differential pressure indicators, and flow indicators. The portable sampling systems can be installed directly on-site without the need for pre-installed sampling ports or stations.

1. The Role of Sampling Devices: The First Line of Defense for Process Safety

➀Gas-tight Requirements in High-pressure Environments

As industrial processes grow more complex, the range of pressure and composition variations in fluids becomes broader. A sampling system with high gas-tightness and low leakage is now a standard requirement in high-risk environments. Even the smallest leak can contaminate samples, compromise test accuracy, or cause hazardous gas releases and environmental incidents. At JPE, “low leakage rate” is a core design priority, achieved through sealed structure optimization, material selection, and refined manufacturing processes to enhance gas-tightness and ensure sample integrity and operational safety.

➁Balancing Environmental Compliance and Operational Ease

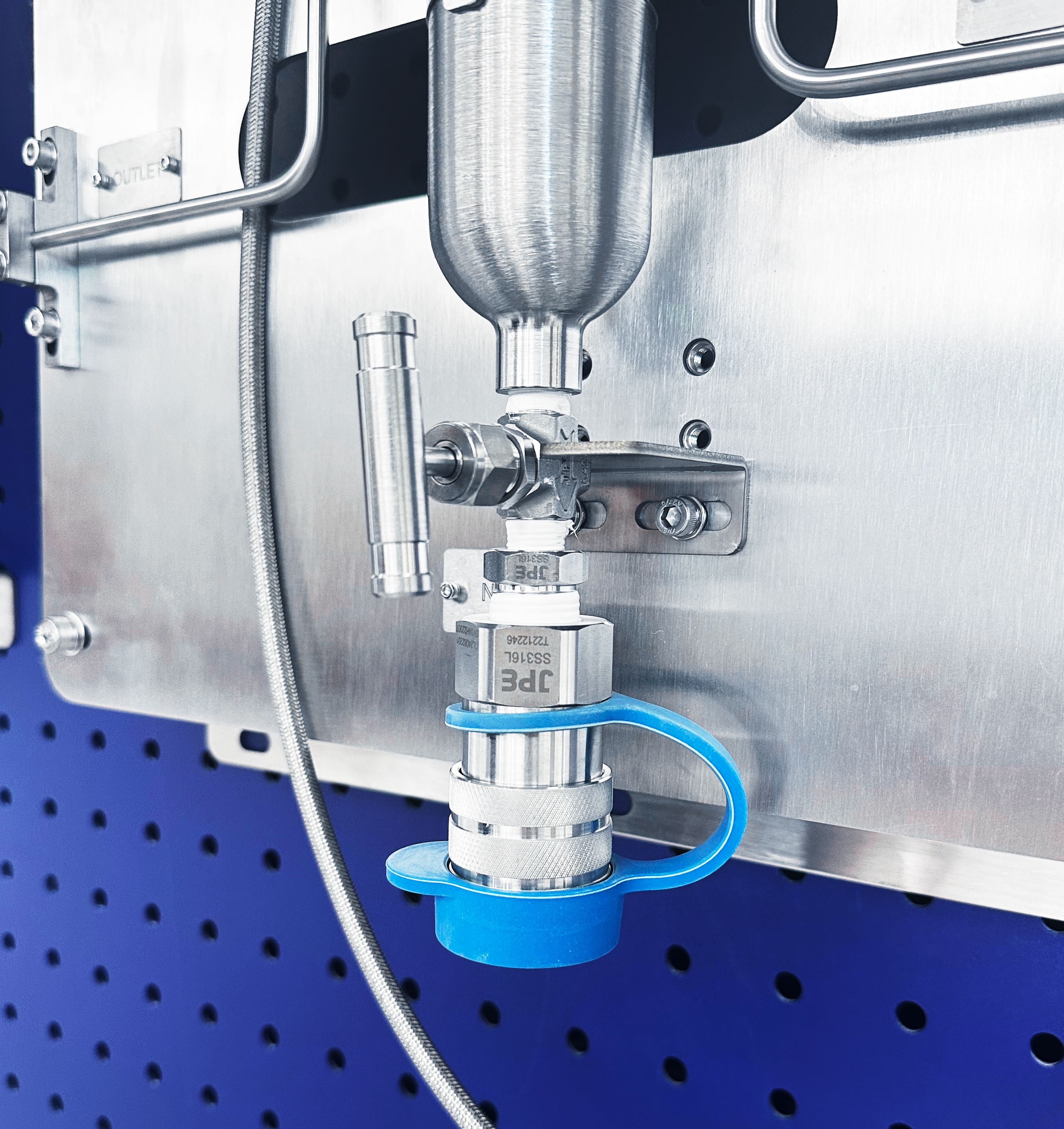

Beyond sample purity and equipment reliability, ease of operation and compliance with environmental regulations are key considerations. JPE sampling systems emphasize semi-automatic operation and incorporate quick-connect fittings to minimize operator exposure risks and prevent waste due to operational errors.

2. From Technology to Practice: Systematic Development of Reliable Sampling Solutions

➀Stress-free Piping Design: Enhanced Stability and Maintenance Convenience

JPE adopts stress-free design principles in piping layouts, carefully planning pipe lengths, bend radii, and support points to avoid material stress concentration from bends or thermal expansion and contraction. This design not only extends the service life of components and fittings but also simplifies disassembly and maintenance, significantly reducing downtime during factory maintenance.

➁Flat-face Quick Connectors: Plug-and-Play with Reliable Sealing

To further improve operational safety, JPE systems use flat-face quick connectors. These connectors ensure minimal leakage during connection or disconnection and automatically seal upon insertion, eliminating issues like wear or loosening common in traditional threaded joints. This is especially critical in applications involving toxic or highly volatile substances.

➂Purge Function Design: Ensuring Sample Accuracy and Preventing Cross-contamination

For scenarios involving frequent sampling or multiple fluid types, JPE offers comprehensive purge system designs. Purging involves flushing the sampling line with inert gas (e.g., nitrogen) or process gas prior to each sampling to eliminate residuals from previous samples, thus preventing cross-contamination. The purge system can be integrated or modular, with added check valves and pressure regulators to maintain stable flow and correct direction during purging, ensuring thorough cleaning.

3. A Holistic Approach: Key Factors for Pre-selection System Evaluation

➀Comprehensive Review of Fluid Properties and Operating Conditions

When selecting a sampling system, relying solely on pressure and temperature parameters is insufficient. JPE recommends reviewing the following factors during the planning stage:

●Fluid state: gas or liquid

●Operating pressure and temperature range

●Chemical properties: corrosive, toxic, or volatile

●Sampling frequency and continuity

●Installation environment: requirements for explosion-proofing, weather resistance, or protective enclosures

These factors determine the material and configuration of the sampling cylinders, whether cooling or purge systems are needed, and if reserve volume space must be allocated. JPE offers modular model selection and can customize systems to meet specific needs, ensuring seamless integration with existing processes.

4. Sample Handling Details: Cylinder Filling and Reserve Volume Design

➀Filling Methods Based on Fluid Characteristics

Proper cylinder filling ensures sample integrity. For liquid samples, bottom-up filling is typically used to ensure complete filling and to accommodate an Outage Tube that provides expansion space to prevent pressure buildup from overheating. For gas samples, top-down filling allows condensed liquids to settle and be expelled, preserving sample purity.

➁The Importance of Outage Tubes: Preventing Pressure Anomalies

Liquids are incompressible. Without appropriate vapor space, temperature rises can lead to dangerous pressure spikes. Based on fluid characteristics and environmental variables, JPE designs outage tubes of suitable length and placement to control maximum fill volume, ensuring operational safety and compliance with international transport and storage regulations.

5. Diverse Sampling Bottle Options and Material Selections

➀Stainless Steel and Glass Bottles Available

JPE provides various bottle types for different operating environments. Stainless steel cylinders come in single- or double-ended configurations and are sealed using TIG welding under argon protection to ensure leak-proof, pressure-resistant construction.

Available stainless steel capacities include 150ml, 300ml, 500ml, and 1000ml, with pressure ratings of 2000 psig or 5000 psig. For highly reactive substances, high-strength glass sampling bottles are also available in 100ml, 250ml, and 500ml sizes to avoid metal reactivity or adsorption issues.

JPE’s sampling systems are not just standalone devices—they represent comprehensive solutions shaped by real-world experience, engineering support, and a commitment to safety. From material selection and sealing design to operational convenience and integrated system modules, every detail is crafted to achieve the industrial vision of "low leakage, high safety, and high efficiency." As the industry advances toward high-pressure, trace analysis, and clean energy applications, JPE continues to refine its products to deliver more stable and intelligent sampling solutions for modern industrial processes.