JPE Industry Insights|In-Depth Look at Compression Fitting Sealing Principles – The Technology Behind Leak-Free Sealing

2025-06-17

Industry Knowledge Popularization

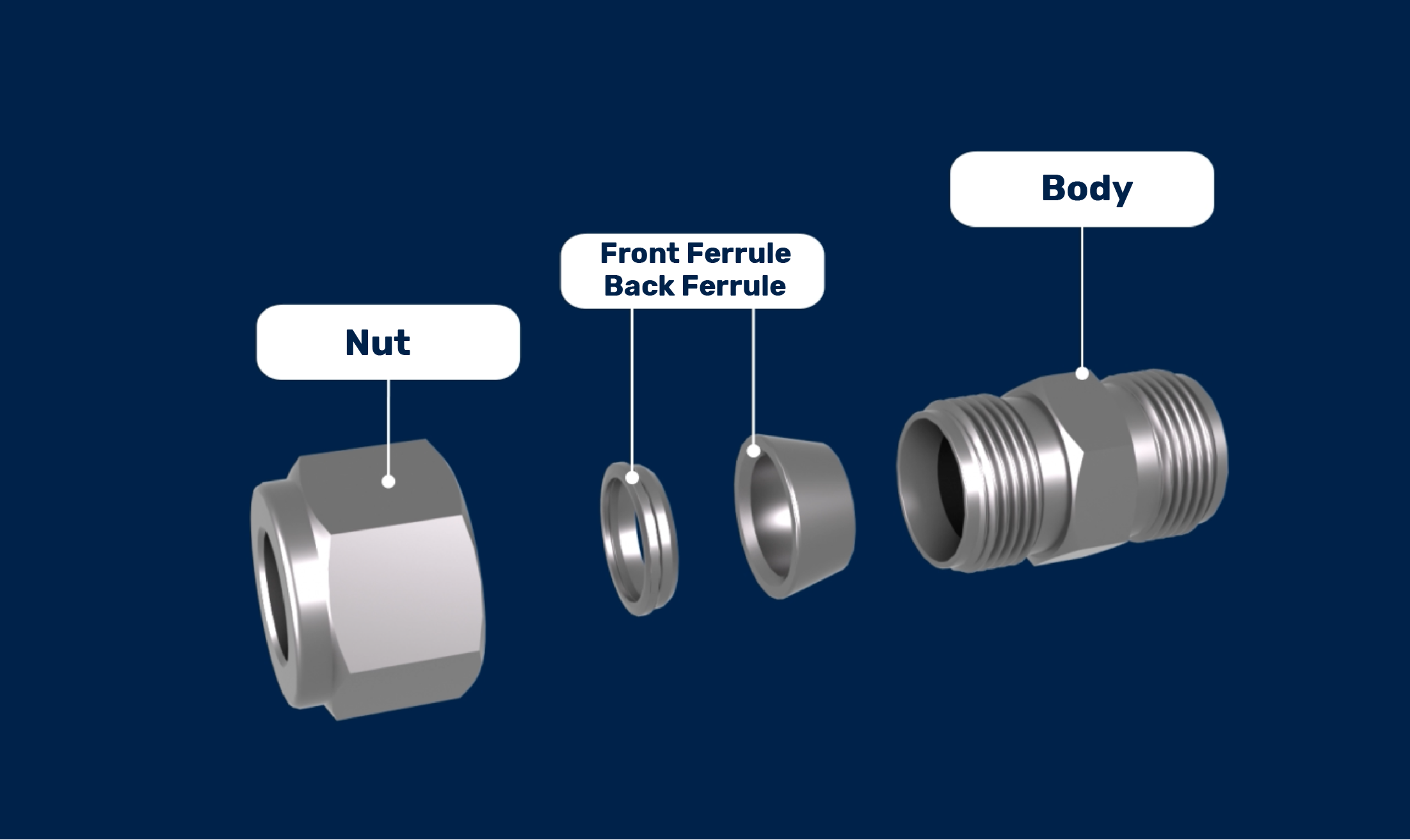

Compression fittings play a critical role in instrumentation systems by providing highly reliable sealing, ensuring the safe and leak-free transmission of fluids or gases. The core of this technology lies in its unique mechanical sealing principle, which consists of four key components—all precisely manufactured from high-strength stainless steel or special alloys:

1. Body:Features an internal conical surface that guides and compresses the front ferrule.

2. Front Ferrule:Provides the primary seal by closely fitting the outer diameter of the tube.

3. Back Ferrule:Provides secondary support and clamping, preventing pull-out or loosening due to vibration.

4. Nut:When tightened, delivers axial thrust that drives the sealing process.

1. Step-by-Step Breakdown of the Sealing Mechanism

The sealing process begins when the nut is tightened. As the nut is rotated, it advances forward mechanically along the threads. This forward thrust first acts on the back ferrule, pushing it ahead. The back ferrule, in turn, transmits this force to the front ferrule, driving it forward as well.

Inside the body of the fitting Inside the body of the fitting is a precisely angled internal slope. As the front ferrule continues to advance, it comes into contact with this slope and is subjected to inward compression. This compression gradually eliminates the small clearance between the inner diameter of the front ferrule and the outer diameter of the tube. In other words, the front ferrule is reshaped to tightly conform to the outer surface of the tube.

As the back ferrule pushes further, the front ferrule not only moves forward but also contracts inward due to the angled compression. During this process, the rear end of the front ferrule slightly lifts and forms the first key sealing zone with the conical surface of the body.

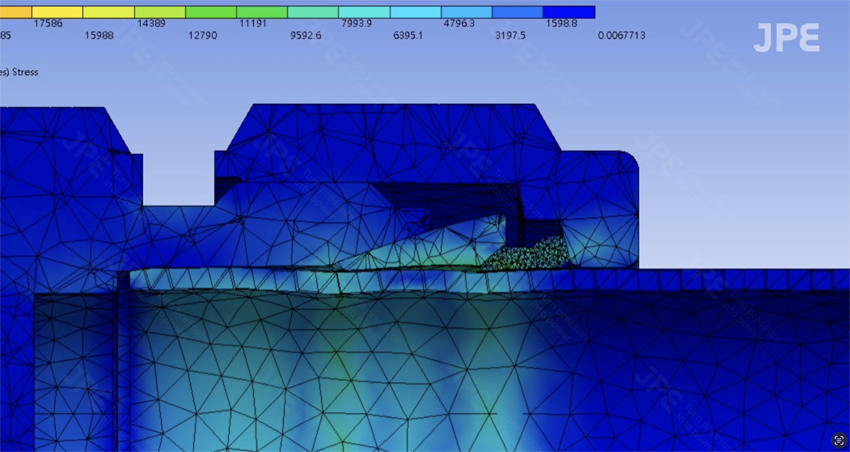

2. Force Distribution and Formation of Dual Sealing

As the nut continues to tighten, a sealed zone gradually forms between the fitting body and the tubing. At this stage, the pressure in the sealing regions on both sides of the ferrule increases. Once the nut is tightened to a certain point, a secure sealing state is established at the front zone near the compression fitting.

It’s important to note that the stability of the seal also depends on the degree of tube deformation and the increased contact area between the body’s slope and the front ferrule. As the tube undergoes more deformation and the contact surface expands, greater resistance is created. This resistance forces the back ferrule to move further inward. This inward movement is crucial—it creates a second strong support on the tube, providing additional sealing assurance and mechanical holding force, effectively preventing the tube from loosening or falling out.

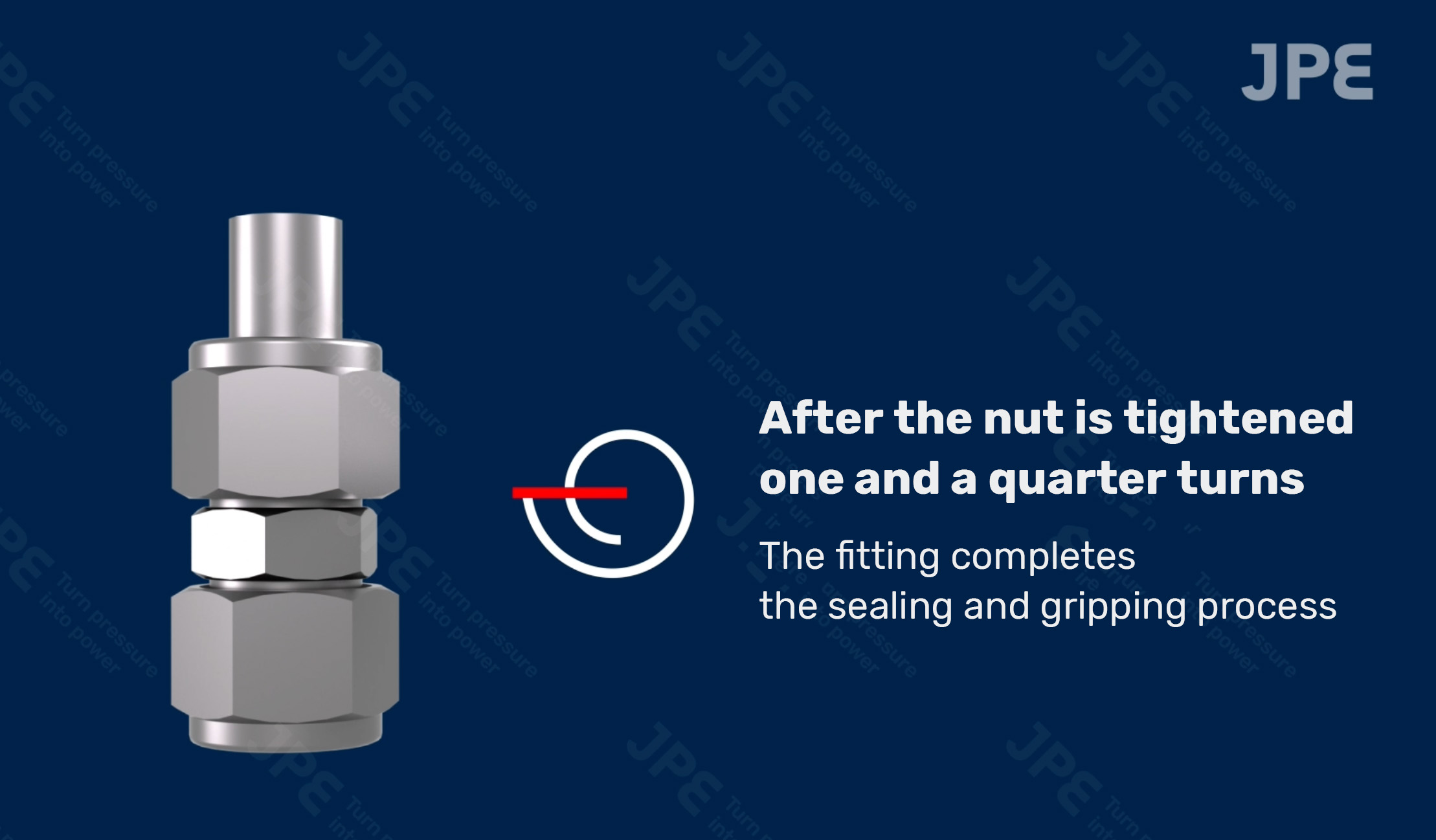

Finally, when the nut is tightened by one and a quarter turns, the fitting completes its dual function: sealing and securely gripping the tube. It’s worth noting that for smaller fittings,only 1/8 of a turn is needed to achieve optimal sealing performance due to their compact size.

The sealing principle of a compression fitting masterfully combines mechanical thrust, angled surface compression, and material deformation to achieve highly reliable sealing. Its dual-sealing design not only effectively prevents fluid leakage but also firmly secures the tubing, ensuring the stable and safe operation of the entire instrumentation system.