JPE Industry Insights|Seal Material Selection Guide: NBR, FKM, and FFKM

2025-10-15

Industry Knowledge Popularization

【Introduction】

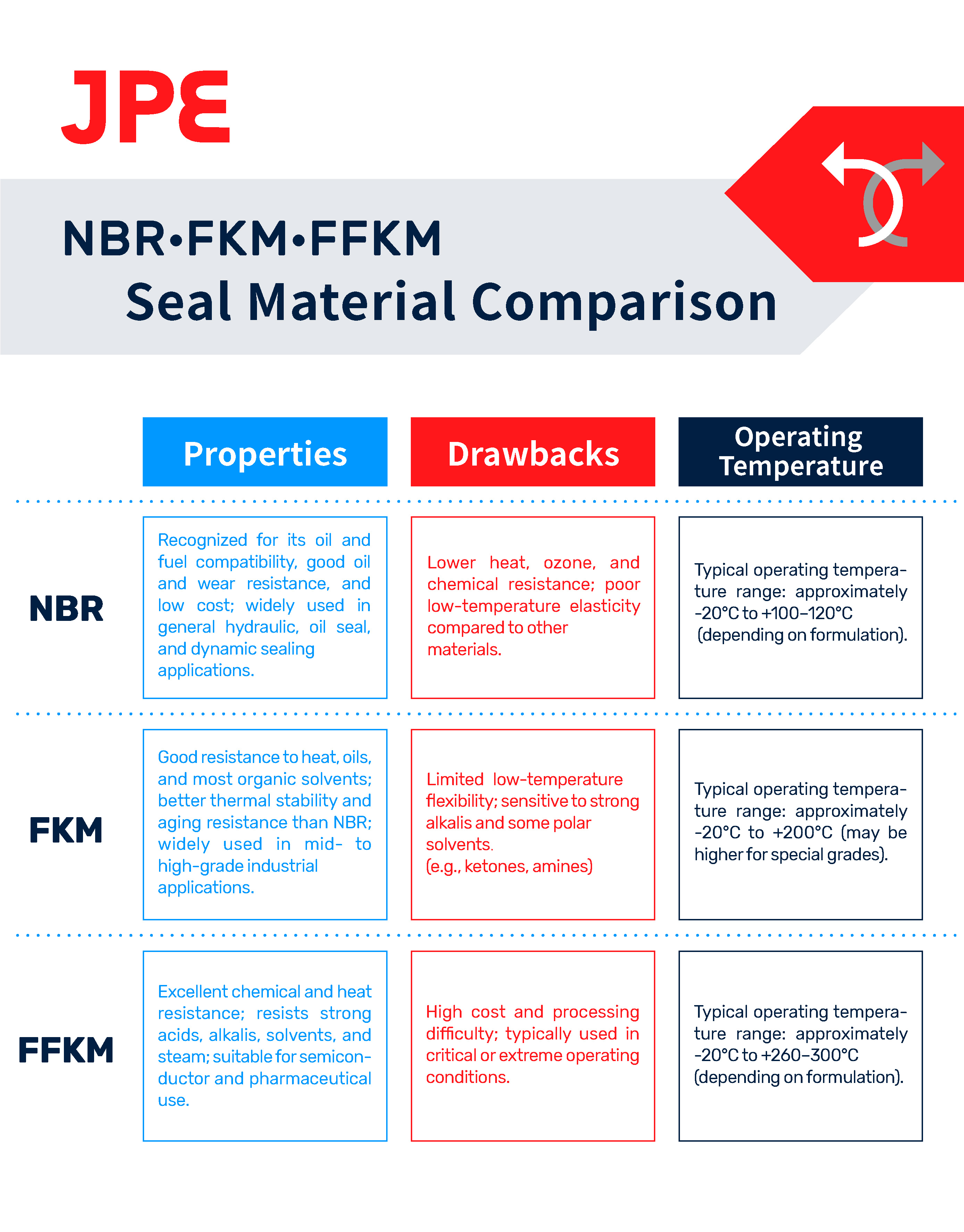

In valve and fluid fitting applications, NBR, FKM, and FFKM each have their own strengths and limitations. Understanding their differences in chemical resistance, temperature tolerance, mechanical durability, and cost can help you make precise decisions in seal design and material selection.

Part 1

Quick Overview of the Three Materials

Part 2

Key Performance Comparison

A. Chemical Resistance: FFKM > FKM > NBR

FFKM is resistant to almost all chemicals; NBR performs well with oils but poorly against acids, alkalis, and polar solvents.

B. Temperature Resistance: FFKM > FKM > NBR

FFKM and FKM maintain stability under high temperatures.

C. Oil/Fuel Resistance: FKM ≧ NBR > FFKM

All offer oil resistance depending on formulation; NBR is highly economical for mineral oil applications.

D. Low-Temperature Flexibility: NBR > FFKM ≧ FKM

NBR performs better in low-temperature environments under general conditions.

E. Compression Set/Longevity: FFKM > FKM > NBR

FFKM offers the best stability and longest service life.

F. Permeability/Outgassing & Purity:

FFKM has the lowest permeability (ideal for high-purity applications); NBR has the highest (may lead to more vapor emission or contamination).

G. Cost: FFKM >> FKM >> NBR

Material choice should consider total ownership cost and downtime risk.

Part 3

Material Selection Recommendations for Valve and Fluid Systems

• For systems using oils, hydraulic fluids, or general fuels with cost sensitivity → Choose NBR. Ideal for dynamic seals and applications in ambient or moderately low temperatures.

• For high-temperature, solvent-resistant, or long-life applications → Choose FKM Suitable for valve seats, O-rings, and dynamic sealing elements. Common in chemical, HVAC, and high-temperature service environments.

• For exposure to strong acids, alkalis, oxidizers, steam, or ultra-clean conditions (semiconductors, pharmaceuticals, specialty chemicals) → Choose FFKM. Despite higher costs, it significantly reduces leakage and unplanned shutdown risks.

• For dynamic or high-pressure systems: When friction and wear are critical and low permeability is required → choose FFKM or specially filled FKM. For oil-hydraulic systems with frequent movement → properly formulated NBR can be a cost-effective alternative.

Conclusion & Next Steps

Material selection should consider medium composition, operating temperature range, pressure conditions, type of sealing (dynamic or static), cleanliness requirements, and cost constraints.

Provide details about your system’s medium type, temperature range, operating pressure, motion frequency, and cleanliness requirements, and the JPE team will recommend the most suitable JPE-grade material, model, or equivalent alternative for your application.