JPE Industry Knowledge | From High-Pressure Safety and Anti-Hydrogen Embrittlement Design to the Stable Performance of Fittings and Valves in Hydrogen Storage Systems

2023-04-14

Industry Knowledge Popularization

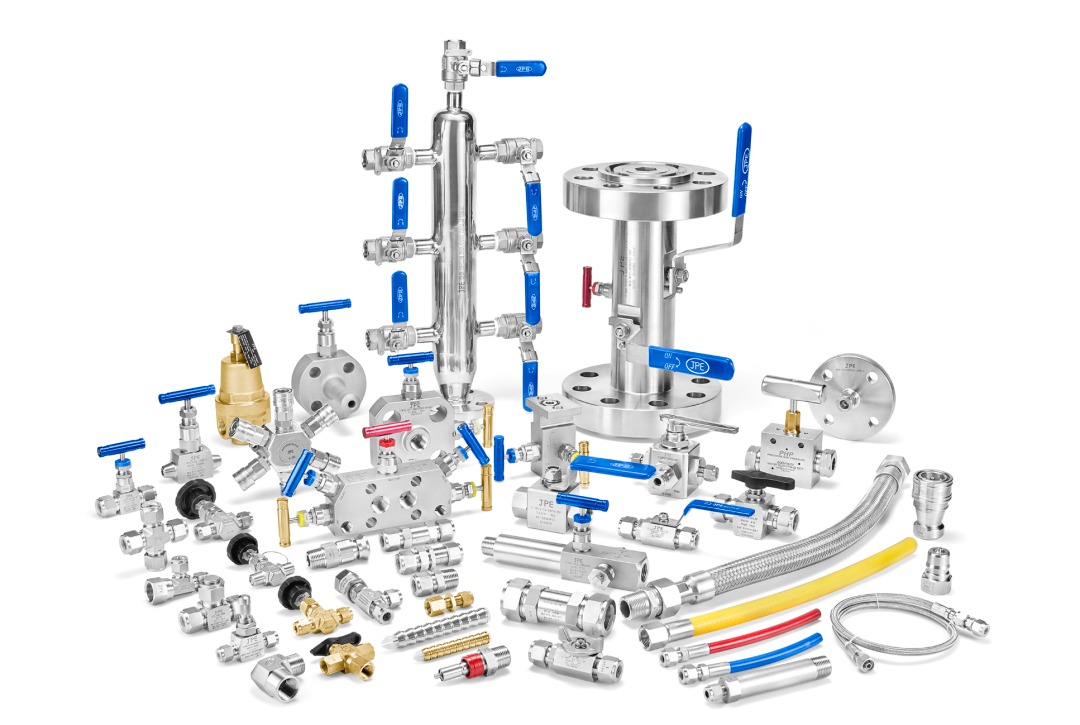

High-density hydrogen storage systems have strict requirements and special standards for their joints and valves to ensure the safe and effective operation of the system during transportation and storage.

To provide users with a comprehensive understanding of the characteristics and requirements of suitable card sleeve and valve products for hydrogen storage systems in the new energy industry, this article focuses on explaining the key features and requirements of valves and card sleeve products for high-pressure hydrogen storage systems. The following summarizes the three main points:

Hydrogen-resistant materials

Hydrogen itself is a highly permeable and unstable fluid, which is prone to chemical reactions with other substances, leading to hydrogen embrittlement of materials. Therefore, the overall stability of the storage system is of paramount importance, which is why JPE always places great emphasis on the quality of raw materials for its valves and fittings products.

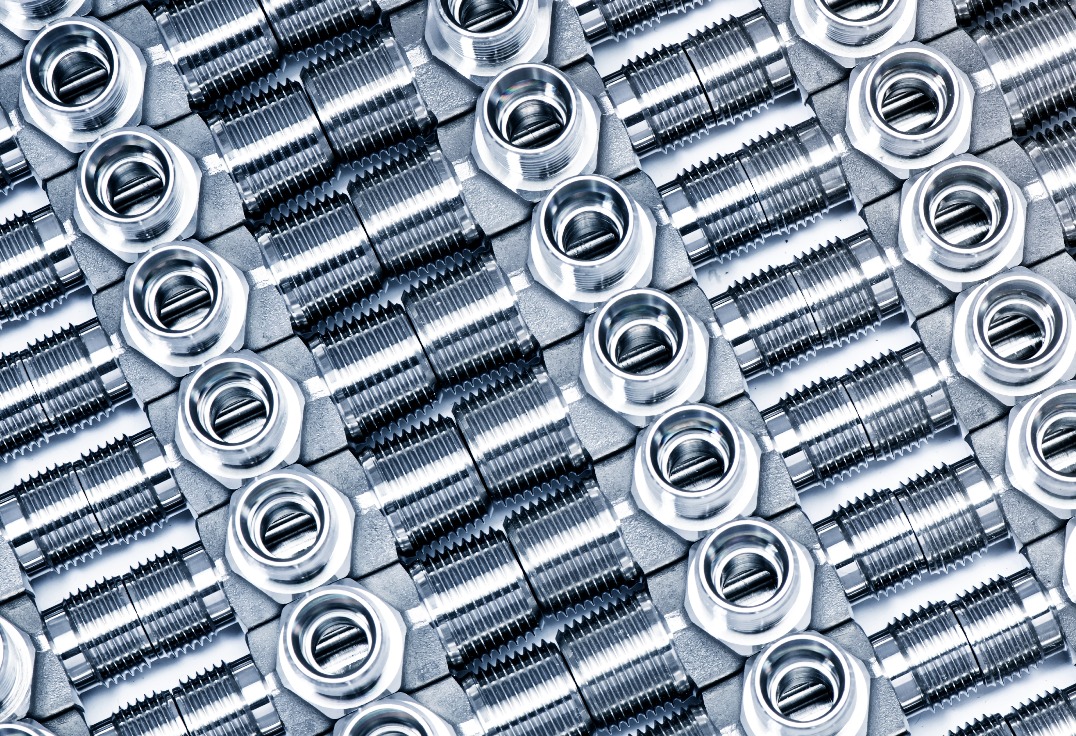

Reliable stainless steel materials are used, or the nickel content is increased on the basis of 316 stainless steel to ensure that the nickel equivalent meets the specification. The stability and corrosion resistance of the product are emphasized to ensure that the hydrogen storage system is compliant and has good hydrogen resistance , providing a high level of safety and stability for the system.

The Combination of Structural Design and Precision Machining

For high-density hydrogen storage systems, there is particular concern for leakage risks. Good structural design is an important foundation to prevent hydrogen gas leakage. Safety considerations, such as pressure relief devices, can prevent major accidents. Precise machining is strictly controlled in the manufacturing process , combined with high-quality sealing materials, to ensure that the system can be fully tightened and has high sealing performance.

High-pressure resistance

Hydrogen gas has a high energy density under high pressure, so valves and card sleeves in the system must not only withstand external high-pressure conditions, but also pass sealing and pressure tests under those conditions to ensure that the system can operate safely under harsh conditions. Two product series, 35MPa and 70MPa, can fully meet this requirement.

Click the image to read more.

JPE's card sleeve and valve products have been widely used in various industries for many years and have received diverse and extensive feedback from users, making them the strongest support for JPE's entry into the new energy industry in recent years. We have also provided explanations on various tests conducted for EC79 certification in the hydrogen energy industry in the past. Please refer to the following link for details:

Click the image to read more.

The JPE team looks forward to working with partners in the new energy industry to jointly develop and strive for the sustainable development of this emerging industry, leading the way towards a better future!