JPE Product Introduction | Common Causes of Check Valve Failure

2023-10-21

Featured Products

In a fluid system, a check valve serves the purpose of opening the valve through fluid pressure, allowing the fluid to flow through. After the fluid has passed, the valve closes due to the mechanical principles of its internal structure, utilizing the reverse flow force to prevent fluid backflow in the pipeline.

Check valves are often installed in pressurized fluid pipeline systems to prevent fluid from flowing back, and they are commonly referred to as non-return valves. Depending on the type of fluid medium and the working conditions of the pipeline system, it is advisable for users to select check valves with different sealing materials.

Check valves come in various forms. Common types found in pipeline systems include lift-type check valves and swing-type check valves. JPE manufactures and sells what is known as instrument check valves in instrumentation systems.

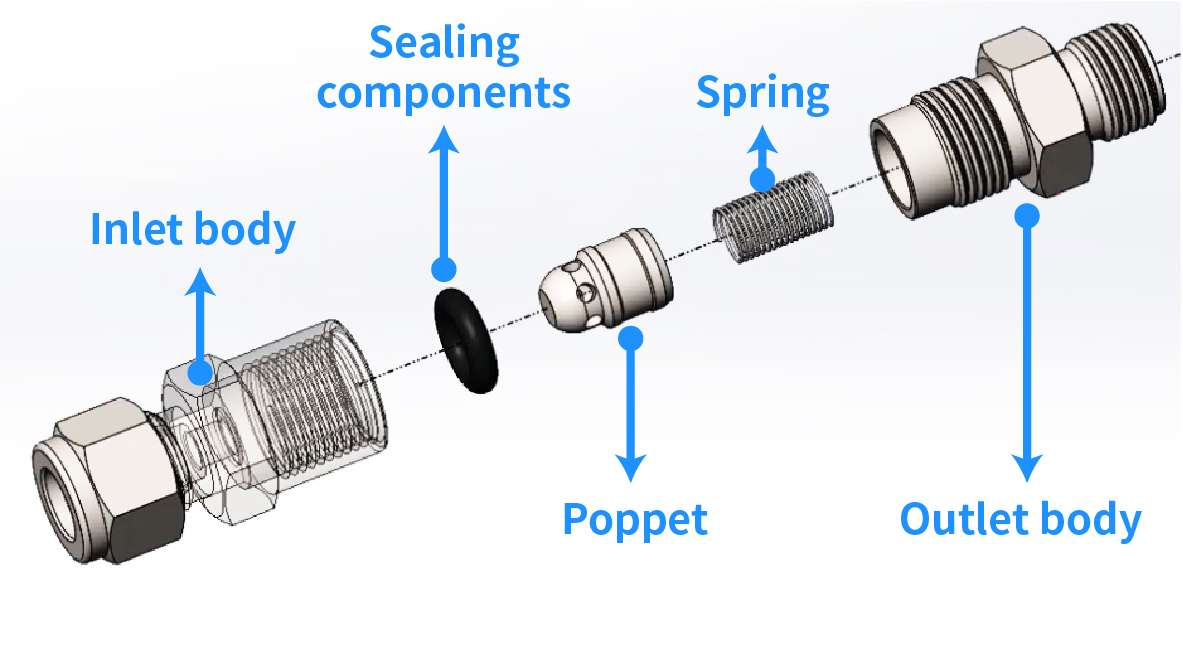

Instrument check valves have a simple design, comprising the inlet body, outlet body, spring, poppet, and sealing components.

The use and installation of check valves require careful attention to various crucial details, particularly in pipeline systems.

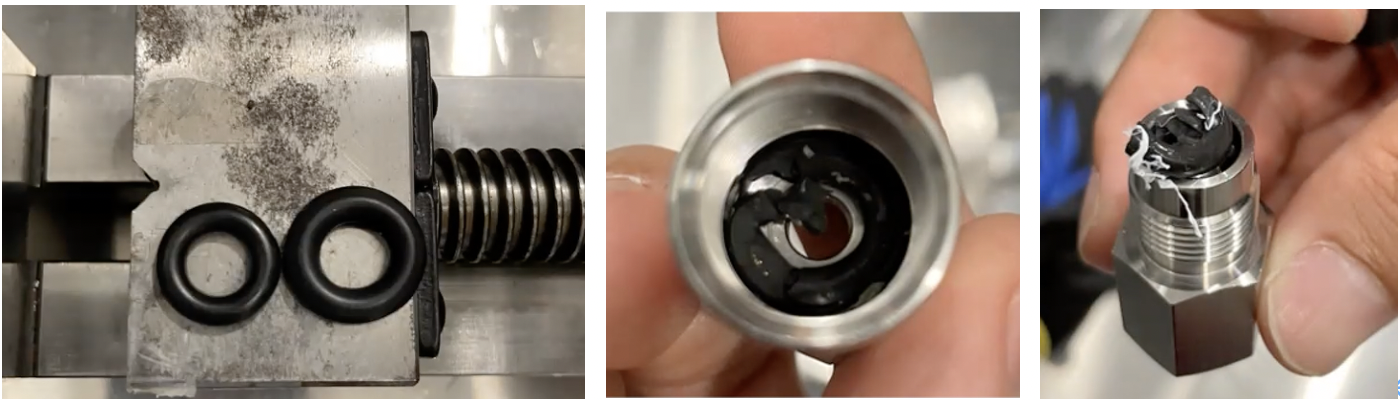

The illustration above highlights issues related to the improper use of check valves.

When faced with unsuitable media or conditions, sealing components may experience problems such as expansion, embrittlement, or loss of elasticity, thereby impacting the effectiveness of check valves.

Here are explanations for two common issues related to the installation and improper use of check valves:

01 The check valve produces a metallic collision sound.

Causes:

Insufficient air flow causes the poppet to act continuously between open and closed positions.

Solutions:

A Replace the spring with one having a lower opening pressure.

B Increase the air flow and pressure; stabilize it, and then return to the required air flow and pressure values.

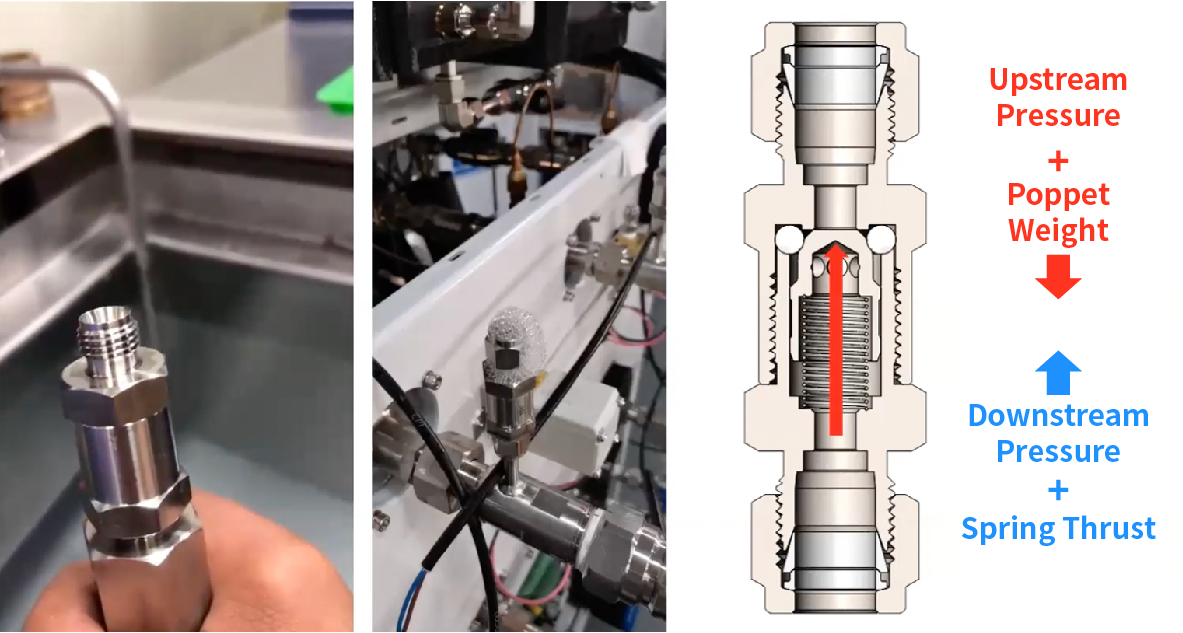

02 Poppet weight is ignored when the check valve is installed vertically.

Causes:

Due to the influence of gravity, when there is insufficient back pressure, the poppet cannot seal.

Solutions:

A Change to a horizontal installation.

B To maintain a vertical installation, factor in the back pressure and find a product suitable for the actual opening pressure.

There are also some common misconceptions about the use of check valves in the market, such as using them as safety relief devices. This is actually incorrect. Check valves are designed solely for controlling one-way fluid flow and should not be used as safety relief devices.

Proper use of check valves ensures the smooth operation of fluid and pipeline systems, enhances safety and maintains system efficiency. For more information about check valves, please feel free to get in touch with JPE's team nearby to obtain further product-related information!

See more JPE Featured Products ➡️