JPE Industry Insights | Hydrogen Storage and Transportation. Key Safety and Material Insights from JPE

2023-10-27

Featured Products

With the growing awareness of green and clean energy sources, companies in the hydrogen energy sector are swiftly advancing in technology, standardization, and resource networking. In light of this new era of industrial development, JPE, as a forward-thinking team dedicated to innovation, fully understands the significance of products, technologies, regulations, and validation in emerging fields. We maintain a sharp focus on standards and regulations, especially in the context of hydrogen energy, where stringent safety requirements are critical.

Hydrogen energy storage, transport, and distribution are pivotal aspects of the entire industry.The challenges posed by high-pressure vessels and the combustible nature of hydrogen gas underscore the strict safety requirements, as well as the need for operational efficiency, precision, reliability, and compatibility across all system components.

Here are some key areas that require our attention:

01 Exceptional Sealing:

In the realm of hydrogen energy, any leaks are almost intolerable. They not only result in energy wastage but also pose safety risks during daily system operations. This is particularly important during refueling and high-pressure hydrogen storage and transport, where leaks can lead to unnecessary hazards in challenging road conditions.

02 Superb Compatibility:

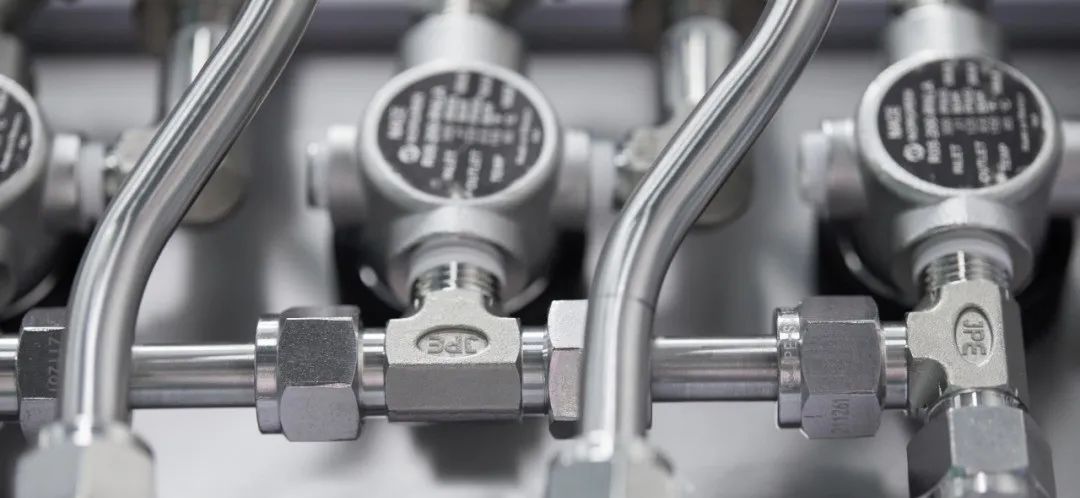

Hydrogen energy systems consist of various precision components that need to work seamlessly together for optimal efficiency. JPE has extensive experience in integration, ensuring compatibility among different series of connectors and valves commonly used in the industry. This approach maximizes system reliability while minimizing potential risks. Having a thorough understanding of component brands, material properties, and universal specifications is instrumental for collaborating with industry experts and achieving rapid integration.

03 Reliable Dependability:

Reliable Dependability: Product reliability is paramount in the hydrogen energy sector, especially since hydrogen storage systems often face unpredictable transportation risks, such as harsh weather conditions and vibrations during transport.JPE excels in showcasing high reliability under various challenging weather and road conditions, as demonstrated through our ASTM F1387 and EC79 product series.Robust product reliability is essential for ensuring safety. In high-pressure and high-density hydrogen flow systems, valves and joint pipelines require strict material chemical composition and mechanical property specifications to withstand potential risks.

04 Optimal Material Selection:

One crucial area of focus is the hydrogen embrittlement of stainless steel and the stability of rubber sealing elements in high-pressure hydrogen energy storage systems.This is why JPE's flare fittings always utilize reliable stainless steel materials and rubber sealing elements that have passed high-pressure hydrogen gas tests.These materials ensure improved stability and corrosion resistance in hydrogen storage systems.

05 Professional Piping Techniques:

Hydrogen energy pipeline systems often involve high-pressure hydrogen gas. Precise bending and connecting of pipelines are essential to optimize joint performance.JPE's professional team can provide technical support for system partners,helping to mitigate leakage risks associated with industrial piping challenges and reduce potential hazards in high-pressure environments. Experienced system piping techniques make operations safer.

JPE has garnered a strong reputation in the hydrogen energy transportation industry through a range of valves and connectors. Our team members not only possess substantial industry experience but also collaborate closely with industry partners to stay abreast of industry developments. We strive for continuous product improvement and innovation, working together with our industry peers to advance and foster innovation within the industry.