JPE Brand Event | Petrochemical Sampling System Case: Customized Solutions for Safer and More Reliable Sampling

2024-05-08

Company Activity

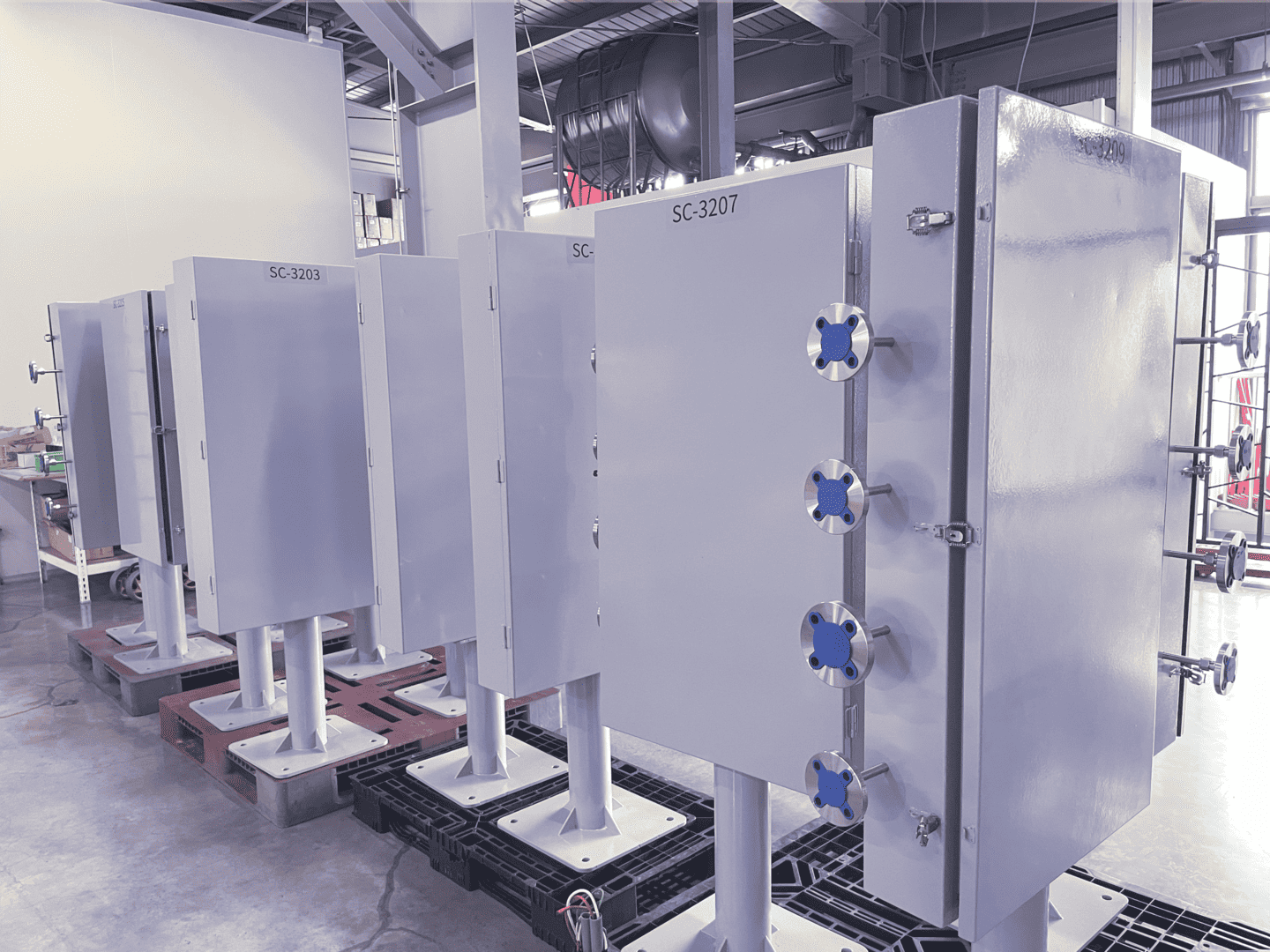

The JPE team has recently achieved another milestone through close technical communication, successfully delivering an order for a renowned steel industry enterprise's Petrochemical Storage and Transportation Center -Spherical Tank Sampling System.

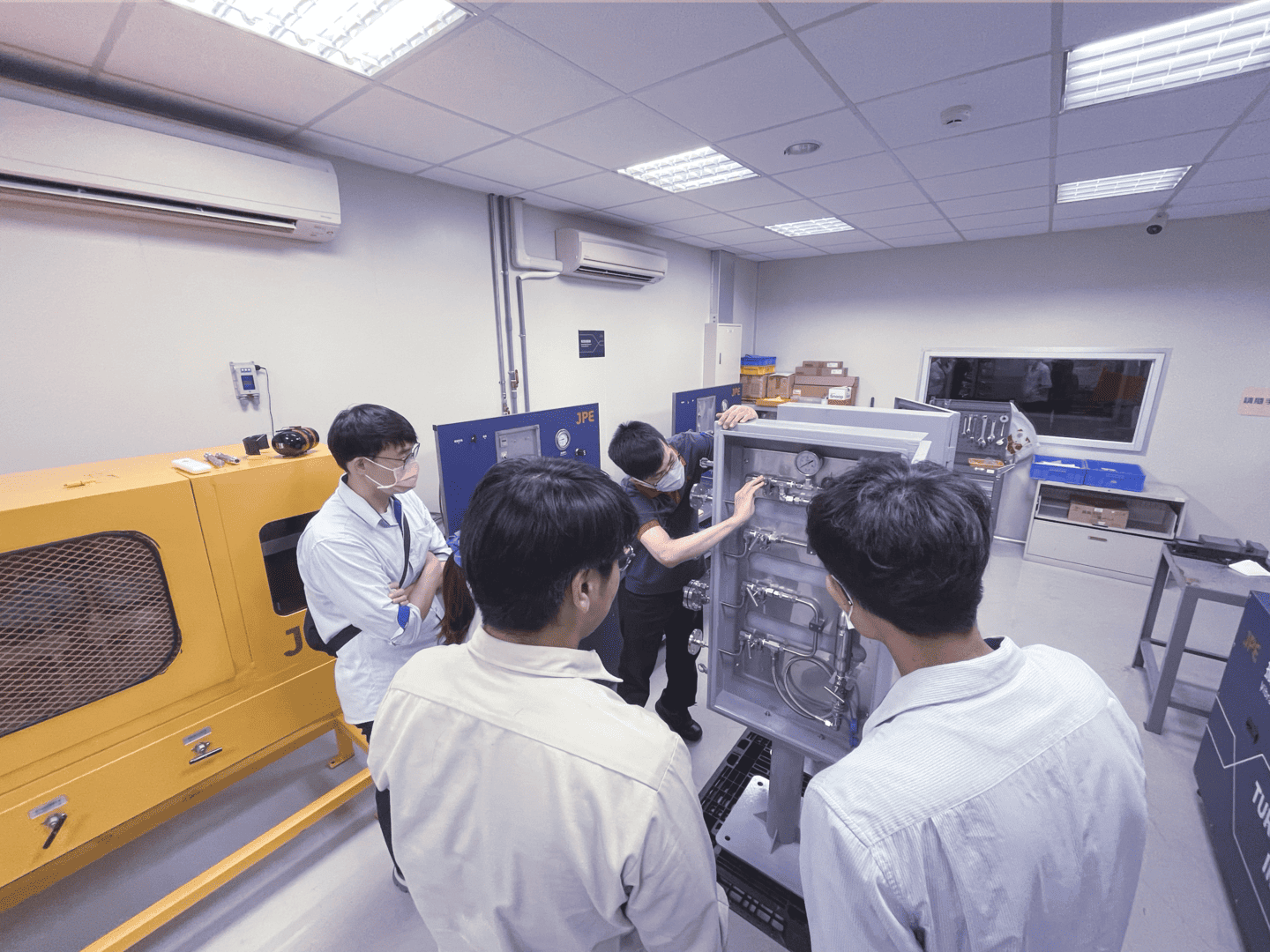

Large-scale petrochemical industrial systems have always been a strong suit for JPE. With a wealth of product application experience, our team can swiftly grasp the requirements of on-site conditions, establish precise and efficient two-way communication and promptly address customer needs. These skills allow us to provide customized solutions tailored to different practical applications.

During the initial meetings, the client's team presented the requirements for the sampling system, in the hope of working with JPE to address the application challenges :

1. The installation site is located in a coastal port environment with stringent geographical and climatic conditions, testing the quality control of material sourcing.

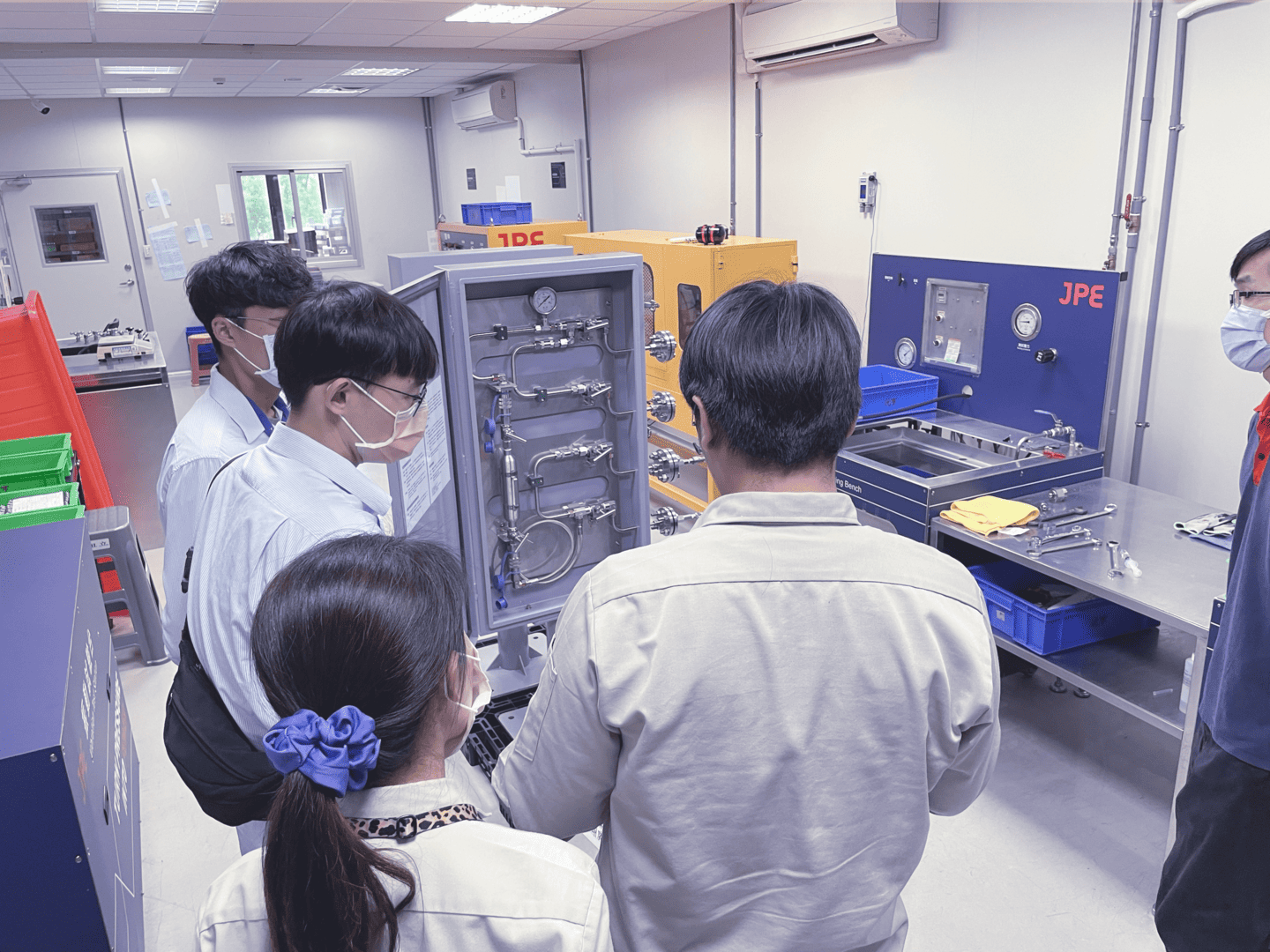

2. The sampling medium is liquefied petroleum gas (LPG). Considering that the medium will vaporize with rising temperatures, the team suggested providing a reserved volume tube to ensure sufficient space for vaporized gas in the sampling bottle and to avoid pressure overload in the sampling bottle after the sampling operation. Through the tubing layout inside the sampling box, routing stress is minimized, reducing the risk of tubing stress corrosion.

3. Considering the contact medium and the on-site conditions, JPE specifically selected flat quick couplings (product links) to minimize the risk of leakage pollution that may occur during sampling operations.

After gaining a thorough understanding of the operating conditions, JPE's technical and sales team accurately identified the challenges and swiftly recommended solutions. JPE's products have also obtained various international certifications. Stable products not only reduce the potential risks of the system but also effectively monitor the quality of sampled products, precisely meeting the customized sampling needs of customers.

In recent years, with the strong support of new and existing customers, JPE has continuously innovated manufacturing technology and introduced advanced equipment, creating a comprehensive manufacturing and management system to enhance production efficiency. In our manufacturing process, we strictly implement the product quality management system and establish a comprehensive production history, always providing customers with high-quality and reliable products.

Through relentless efforts, we are committed to becoming a leading enterprise in instrumentation valves and fittings. We look forward to achieving greater success for our customers and creating more significant commercial value together through the timely delivery of sampling system solutions!