JPE Product Spotlight | Mastering Common Industrial Valves: A Selection Guide for Ball and Needle Valves (Part I)

2026-01-12

Featured Products

How to Select Ball and Needle Valves for Fluid Systems: Specification Comparisons and Purchasing Guide

Section 1: Product Introduction

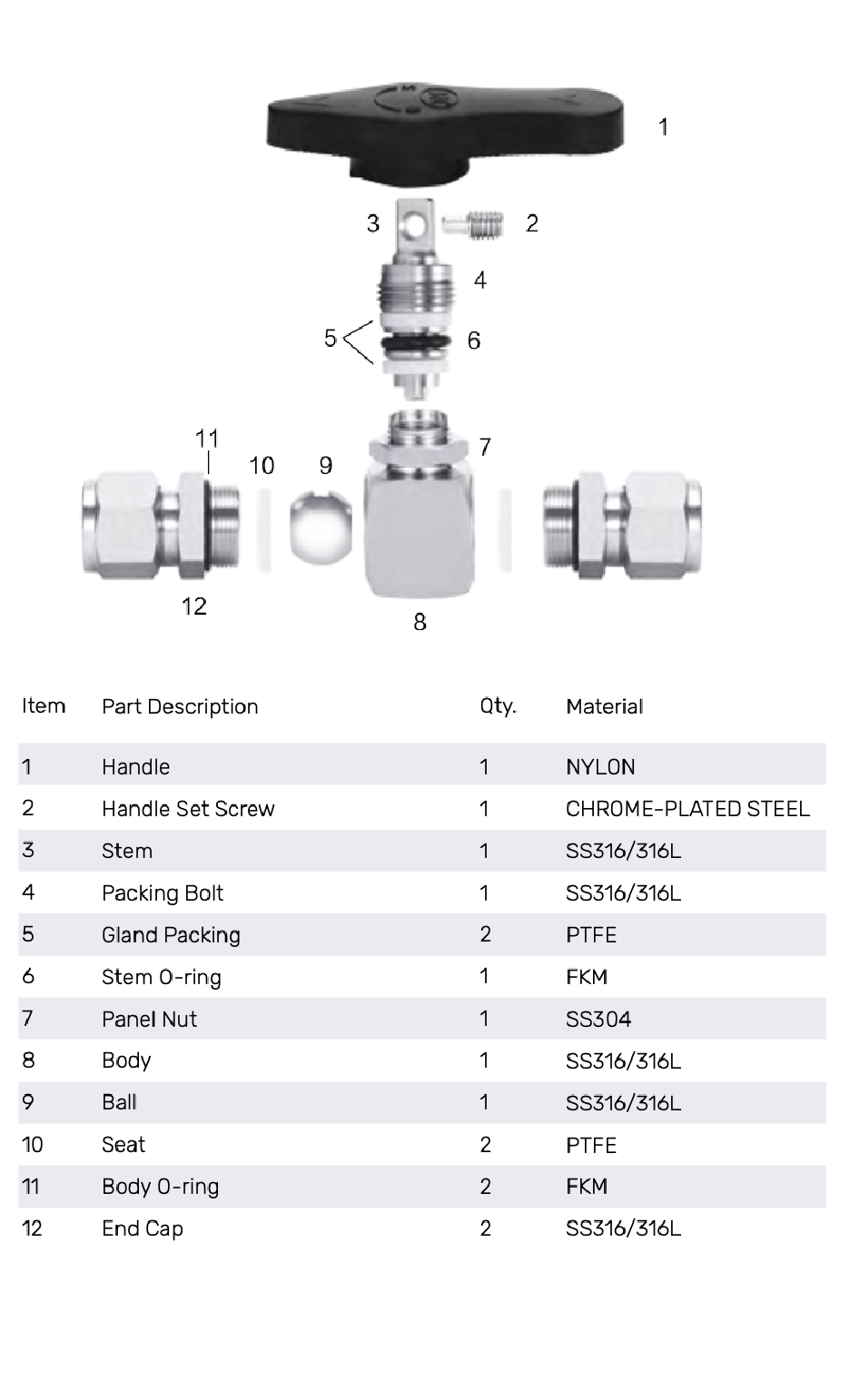

Ball Valves: Ball valves utilize a rotating sphere to open or close the fluid flow. They are quick-acting valves that require only a quarter-turn to fully open or close, characterized by rapid operation, high flow capacity, and low pressure drop. General instrumentation ball valves typically feature a floating ball design, where the ball is not fixed within the valve; instead, the pressure of the medium pushes the ball against the seat to create a seal, providing excellent shut-off performance. Due to their simple structure and few internal parts, ball valves are less prone to leakage and are easy to maintain, making them suitable for applications requiring quick operation and tight shut-off.

Ball valves are commonly used for on/off control in liquid or gas pipelines, spanning industries such as oil & gas, chemicals, and utilities. Their core function is to rapidly cut off, distribute, or change the flow direction of the medium by rotating the ball.

However, ball valves are not suitable for prolonged throttling or fine adjustments. Keeping them in a semi-open position for extended periods may cause seat wear or unstable vibration. For clean or high-purity systems, degreased ball valves can be selected to prevent volatile contaminants from affecting the quality of the medium.

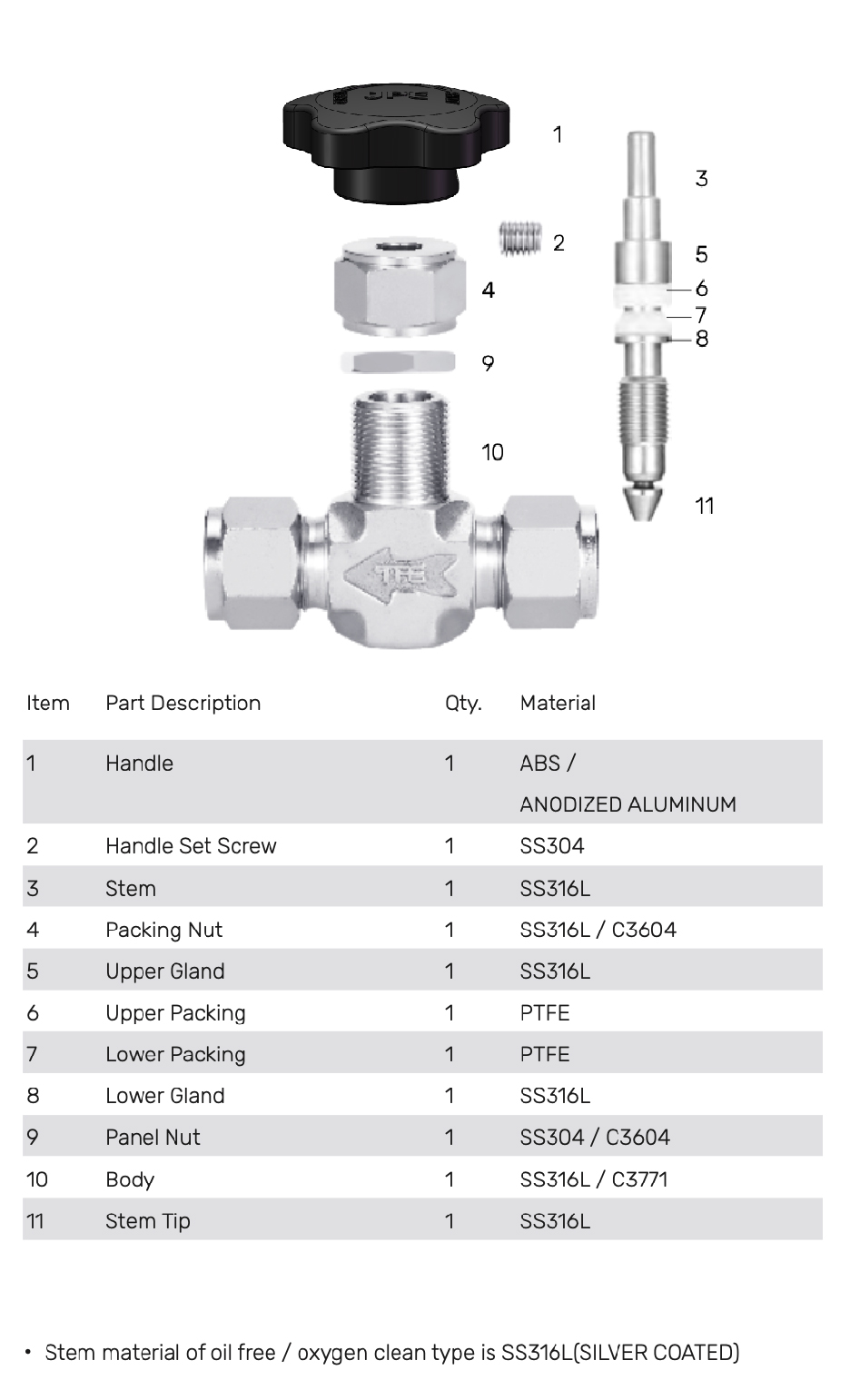

Needle Valves: Needle valves employ a slender, needle-like plunger that fits into the seat to control fluid. They are operated via a multi-turn handwheel, allowing for flow adjustment.

The threaded stem of the needle valve provides precise throttling capabilities, making them suitable for applications requiring fine control of flow or pressure, such as instrument sampling, flow metering, and pressure regulation. Due to the narrow flow path, needle valves handle relatively small flow rates, but their small-bore seats can withstand high pressure differentials and control pressure drop effectively.

Needle valves are frequently used for the precise control of gases and liquids, ensuring stable micro-flow delivery in chemical processes, HVAC fine-tuning, laboratories, and semiconductor systems. It should be noted that needle valves have a long opening/closing travel distance and cannot cut off fluid instantly like ball valves. Additionally, it is difficult to visually judge the valve opening degree from the handwheel position alone. Needle valves are typically available in straight or angle patterns to meet piping layout requirements through different flow direction designs.

Section 2: Key Performance Differences and Comparison

Body Material: JPE ball and needle valves primarily use 316L Stainless Steel for the valve body due to its excellent corrosion resistance and mechanical strength in most chemical fluids and industrial gases. 316L not only resists corrosion from acidic and alkaline media but is also suitable for demanding environments such as high-purity gases. Some products, such as the NV series needle valves, also offer Brass options to lower costs for non-corrosive media; however, brass has a lower pressure tolerance (generally limited to under 3000 psig) and is not suitable for highly corrosive or high-purity systems.

Sealing Material: The choice of sealing material directly impacts the valve's temperature resistance, pressure resistance, and chemical compatibility. Common JPE sealing combinations include:

PTFE (Polytetrafluoroethylene): Featuring excellent chemical inertness and a low coefficient of friction, PTFE is commonly used as a seat material in ball valves to ensure smooth operation and airtight sealing. PTFE withstands most chemicals and resists aging, but its maximum operating temperature is approximately 204°C. Therefore, PTFE is suitable for general processes ranging from -196°C to medium temperatures; if temperatures exceed this limit, other materials must be used.

PEEK (Polyetheretherketone): Known for high strength and rigidity, PEEK maintains dimensional stability under high temperature and pressure. PEEK seals are often used in high-pressure ball valves, as they can withstand higher temperatures (above 230°C) and resist deformation under high pressure. For example, the JPE TNBV Trunnion Ball Valve series utilizes PEEK seats to meet conditions up to 6000 psig and 232°C. PEEK is suitable for harsh processes but comes at a higher cost.

FKM (Fluoroelastomer): A fluorinated rubber material used for O-rings, offering good heat and oil resistance. FKM is commonly used as an auxiliary seal for stems or seats, suitable for general industrial environments. Its temperature resistance reaches approximately 204°C, with good stability against most oils and solvents, but it is not suitable for strong acids/alkalis or applications requiring low outgassing in high vacuums.

Graphite Packing: Needle valves utilizing graphite packing can withstand significantly higher temperatures (exceeding 400°C) and possess strong corrosion resistance. The JPE NV33 series offers options for either PTFE or Graphite packing to balance general environmental needs with high-temperature requirements. Unlike PTFE, graphite does not suffer from cold flow deformation at high temperatures, but it may exhibit micro-leakage in low-temperature or vacuum environments, requiring selection based on specific conditions.

In conclusion, the appropriate material combination should be selected based on actual operating conditions, medium chemistry, temperature, and pressure. For instance, 316L stainless steel bodies with PTFE/FFKM seals are suitable for most acidic and alkaline fluids; high-temperature and high-pressure systems tend to favor PEEK seats and graphite packing; while oxygen or high-purity media require grease-free, specially cleaned materials.

Proper material selection extends valve life and ensures long-term reliability.