JPE Product Spotlight | Mastering Common Industrial Valves: A Selection Guide for Ball and Needle Valves (Part II)

2026-01-20

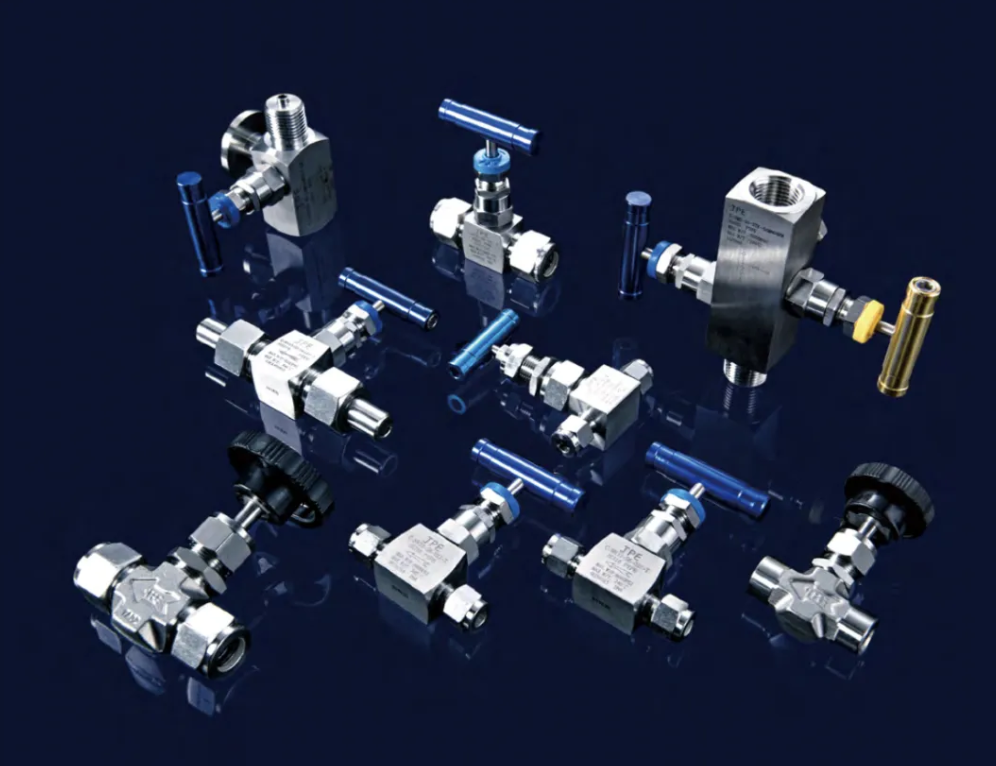

Featured Products

How to Select Ball and Needle Valves for Fluid Systems: Specification Comparisons and Purchasing Guide

Part 1: Operation Method

Ball valves open and close with a 90° rotation of the handle. The operation is highly intuitive, with the handle position clearly indicating the open/close status. Standard JPE ball valves are equipped with plastic or stainless steel handles, and some series allow for the installation of locking devices to prevent accidental operation.

In contrast, needle valves are driven by round handwheels or bar handles. They require multiple turns to fully open or close, meaning they cannot switch states instantly.

The long, tapered stem structure of a needle valve is suitable for fine throttling (flow regulation) but is not suitable for applications requiring quick shut-off. Therefore, in practical applications, ball valves are typically used for high-flow pipelines or systems requiring emergency shut-off, while needle valves are used for branch lines that require precise flow control.

Part 2: Pressure Ratings

Due to differences in series design, the Maximum Allowable Working Pressure (MAWP) of valves varies significantly. For JPE instrumentation ball valves:

• 2-Piece Ball Valves (2BV Series): Rated at 1000 psig, suitable for general medium-to-low pressure pipelines.

• 3-Piece Ball Valves (3BV Series): Rated at 3000 psig, designed with higher strength to meet medium-to-high pressure demands.

• Cast Ball Valves (BVL Series): Available in 1 to 3-piece structures with specifications ranging from 1000 to 3000 psig (e.g., BVL2 2-piece full port can reach 2000 psig). Due to the cast body, the applicable pressure of the BVL series is usually slightly lower than equivalent forged valves.

• Trunnion High Pressure Ball Valves (TNBV Series): Rated up to 6000 psig (approx. 414 bar), designed specifically for high-pressure systems.

Regarding needle valves, most JPE instrumentation needle valves are rated at 6000 psig (approx. 414 bar). Among them, the NV11/NV12 forged needle valve series can reach 6000 psig when made of stainless steel, but are limited to approximately 3000 psig if made of brass. The NV33 series is manufactured entirely from 316L stainless steel, rated at 6000 psig, and offers a higher structural safety margin. In short, when selecting a valve, ensure that both the system's normal operating pressure and peak pressure fall within the valve's rated range, while also considering an appropriate safety factor. All JPE valves undergo 100% nitrogen pressure testing before leaving the factory to ensure no visible leakage under rated pressure.

Part 3: Temperature Range

The temperature a valve can withstand also depends on the material combination. JPE standard ball valves (PTFE seats, FKM seals) typically have a maximum operating temperature of approximately 204°C. If PEEK seats or graphite seals are selected, the temperature resistance can be raised to 232°C or higher. However, high temperatures often reduce the allowable pressure, so please refer to the specific series' pressure-temperature curves for confirmation.

In cryogenic environments (such as deep-cold liquid gases), general instrumentation ball/needle valves may be unusable due to material embrittlement; JPE offers specialized cryogenic valve models for these choices. In applications, ensure the valve material's operating temperature range covers the system's minimum and maximum temperatures to prevent seal failure or material strength degradation caused by exceeding temperature limits.

Connection Types: To facilitate integration into various pipelines, JPE valves provide diverse end connection forms, including:

• Tube Fittings: Specifically double-ferrule instrumentation tube fittings, suitable for direct connection with stainless steel tubing, ensuring no leakage under high pressure. The 2BV/3BV ball valves and NV series needle valves all feature tube fitting configurations, making them convenient for installation in analytical instrumentation and semiconductor pipelines.

• Threaded Connections: Includes two main categories: NPT and BSP tapered pipe threads (Male or Female). They can connect with various pipe fittings and instruments. Among JPE ball valves, the BVL series mainly features FNPT/FBSP threaded ends; NV needle valves commonly feature MNPT/MNPT, FNPT, and other forms. When selecting, pay attention to thread standard matching and sealing treatments (usually assisted by PTFE tape or thread sealant).

• Welded Ends: Such as Socket Weld or Butt Weld types, used for occasions requiring zero leakage or no thread contamination. JPE high-pressure valves and some NV33 needle valves offer butt weld or socket weld interfaces to meet the integrated connection needs of high-purity or heavy-corrosion process lines.

• Flange Connections: For systems with larger sizes or standardized pipe flange connections, flanged valves can be selected. Although JPE primarily focuses on small-bore instrumentation valves, flange adapters can be used to convert threaded or tube fitting ends into standard flanges.

When comparing series, consider connection types and sizes simultaneously to ensure the valve integrates seamlessly into existing pipelines. JPE offers a wide range of connection sizes from 1/8" to 1" (3mm~25mm), as well as specifications compatible with both metric and imperial systems, meeting diverse market needs.